Processövervakning

Vision 2000-C™ XD and

Vision 2000-E™ XD

High sensitivity RGAs for multi-pressure and

CVD/ALD processes

The Vision 2000-C™ XD and Vision 2000-E™ XD systems allow seamless monitoring of a wide range of semiconductor applications, including the complete ALD, CVD, and Etch processes, from base vacuum to process pressures up to 700 Torr.

Both systems incorporate patented V-lens™ technology, taking the proven performance of the Vision 2000-C and Vision 2000-E systems to a new level of sensitivity and reliability, previously unachievable with conventional quadrupole mass spectrometry systems (QMS).

Key features

- In situ monitoring during chamber clean, passivation and deposition

- Up to 10 times increased sensitivity at lower masses (<15ppb)

- Reliable distinction between gases and background

- UniBloc™ fast-response inlet valve for sampling at background and process pressures

- Integration with a wide range of ALD, CVD, and Etch tools

V-lens™ Technology

Degas processes typically employ inert gases such as Argon or Nitrogen. The use of these gases can be challenging as they generate an elevated baseline in RGAs due to large amounts of chemical background noise caused by metastable decay. This results in reduced sensitivity which can be problematic for manufacturers who want to identify changes in trace gases (which are indicative of issues during the manufacturing process) quickly and easily.

V-lens technology, a unique enabling solution, helps to overcome this issue by providing a consistently low mass independent baseline and detection levels in the low ppb range. This is achieved with unique ion optics that utilize a patented double-focusing and deflection mechanism that significantly reduces background and enhances sensitivity (see figure).

The result is a gas analyzer with limits of detection in the low ppb range without compromise to any other aspect of instrument performance.

This state-of-the-art RGA technology is integrated with Process Eye Professional control platform, a recipe based, user-configurable software program. The combination of V-lens, a closed ion source, and automated inlet allows for sensitive and reproducible monitoring of the complete ALD, CVD, or Etch process cycle.

By maximizing the ratio between ALD, CVD, or Etch chamber gas signals and the gas background in the differentially pumped analyzer housing, the V-lens and closed ion source enables low ppm-level detection for trace contaminants in the process gas.

Closed Ion Source

The closed ion source analyzer is manufactured from vacuum prepared stainless steel and high density alumina ceramics, and features independently replaceable twin filaments to provide built-in backup in the event of a filament failure. The standard system includes a double filter analyzer for increased sensitivity of higher mass species, contamination resistance and enhanced long-term stability.

Remote Vacuum Controller

Each Vision 2000-C XD and Vision 2000-E XD system incorporates a Remote Vacuum Controller (RVC) module that provides fail-safe protection for both the process tool and the RGA. It allows full operation and control of RGA system components (filaments, pumps, inlet valves, bake-out, etc.) from the system PC.

UniBloc™ Inlet Valve

The fast-response UniBloc inlet valve allows sampling at both background and process pressure. When not sampling, both the valve and analyzer are automatically isolated from the process chamber and purged with inert gas. Purging is via the mass spectrometer pumping system, not through the process chamber. Purging is also used during bakeout, reducing initial startup time and residual background recovery time.

For sampling up to 10 Torr, a special 4-valve UniBloc is available for bypass pumping to facilitate the faster transfer of sample gas to the inlet, thereby optimizing inlet response time. Above 10 Torr, the 4-valve configuration is always used. The inlet valve is operated by integrated electronics and controlled via recipes from Process Eye Professional. The required valve selection is made automatically by a gas independent pressure sensor in the UniBloc inlet that also provides a read out of the process chamber total pressure. The internal seals are Kel-F® for compatibility with ALD, CVD, and Etch process gases. The external seals are all metal.

Process Eye™ Professional Control Platform

The Vision 2000-C XD and Vision 2000-E XD analyzers use Process Eye Professional. This highly flexible, modular application uses recipes to specify how the instrument scans, displays data, and responds to the acquired data. Recipes, user configurable using the “Recipe Wizard,” allow customized warnings and alarm levels, triggered whenever the process exceeds preset levels.

Other key parameters can also be set via the recipe. This allows optimization for each stage of the process. Process Eye Professional provides:

- Automated and intelligent operation of MKS RGAs

- Recipes for automated calibration

- Flexible scanning — “Bar Chart”, “Analog”, and “Peak Jump” modes can be associated with data trend displays

- Intelligent, user defined warnings and alarms include a suggested diagnosis of the fault condition and a recommendation for its solution

- Optional ability to read data from other sensors using analog inputs and external events by digital inputs

- Data buffer for quick on-line review of recent data

- Full storage of all data for review and analysis

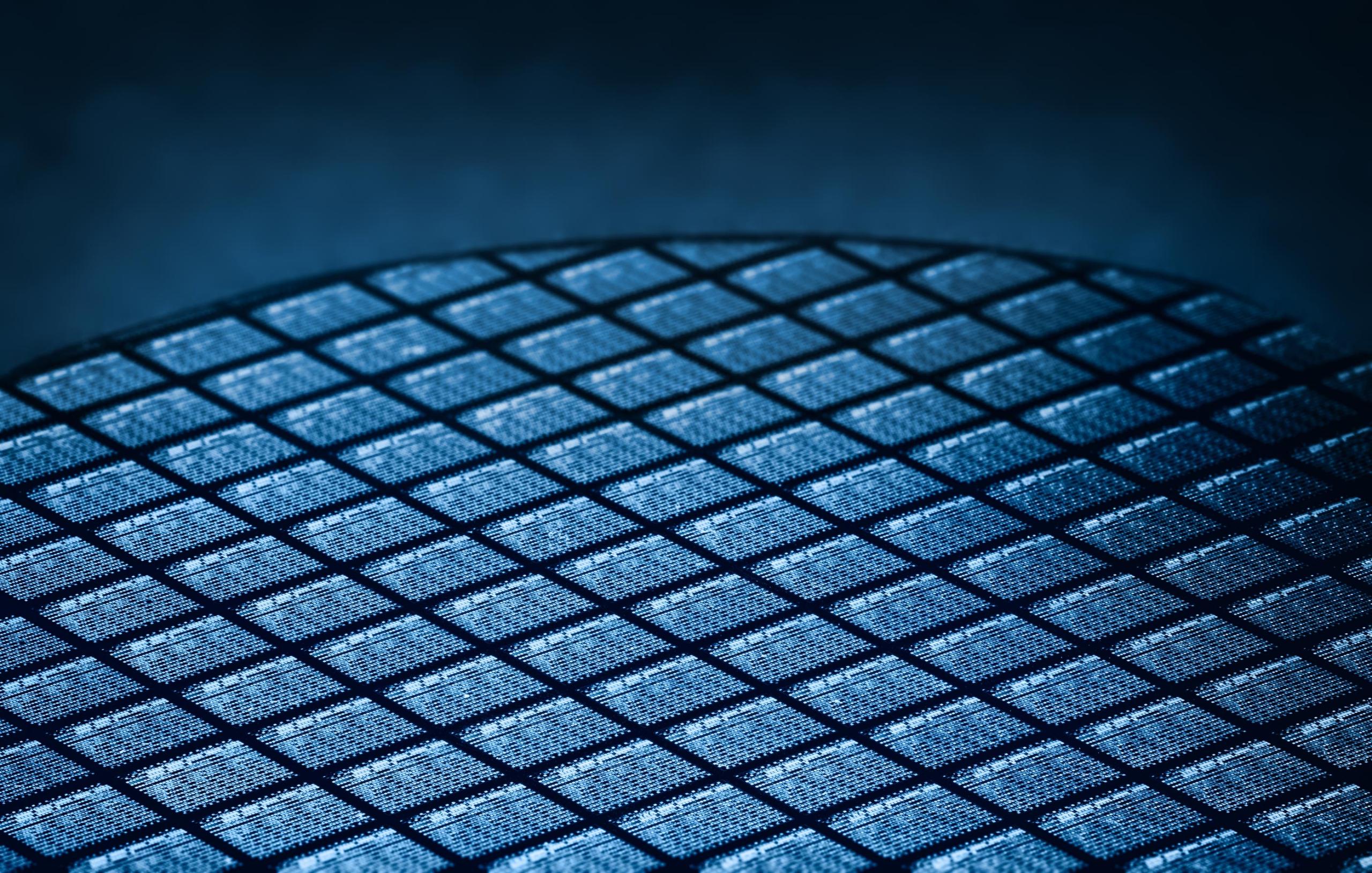

TOOLweb® RGA

Using the TOOLweb RGA sensor integration option for process tools, the Vision 2000-C XD and Vision 2000-E XD can be used as a degas chamber sensor in a completely automated process environment (Figure 4). TOOLweb RGA maintains a constant monitoring of tool activities with all sensor data being framed by wafer logistics before alarm models are applied. Full alarm and data reporting to the FAB host and FDC are available allowing real-time monitoring of chamber conditions and flagging of any process excursions from ideal conditions.